Lean construction offers powerful ways to reduce wasted time and money

Home builders in major markets across the globe face a far different market than in 2021. As rising mortgage interest rates price ever more potential buyers out of the market for homes, builders see less demand for new home construction. As a result, the current state of the construction industry has builders concerned for the future health of their business and looking to newer methods such as lean construction.

The way forward is rethinking how home builds are managed. With decreasing volume and sentiment, home builders need to ensure each home project they undertake earns a fair profit. Fortunately, builders can learn from the experience of other industries that have battled the same concern for efficient job management.

You can achieve sustainable profitability when excess costs and inefficient activity are wrung out of the business. In other industries, project managers have successfully done this using lean philosophy. Construction companies and home builders have adapted this into lean construction practices.

Adopting lean construction practices in home construction

Lean management, more traditionally applied to centralized manufacturing like automobiles, helps the home builder continuously improve to reduce wasteful spending and inefficient labor practices at the job site. But there are other benefits—like giving the entire build team a greater say in best practices and job site safety.

The idea of lean management originates with manufacturing concepts first tried by Taiichi Ohno and Shigeo Shingo beginning in the mid-1950s under the Toyota production system. Ohno identified seven areas of waste, and competitive builders recognize many of these as they manage their own construction projects.

How lean construction benefits the home builder

Home builders like you may not think of what you do as lean construction, but your concern for minimizing waste is very similar. It’s easy to imagine how ordering too many materials blows your budget or how ordering not enough results in wasted time and money on last-minute runs to the lumber yard.

When you work to eliminate waste in your build and gain efficient job management, you are solving the same kind of problems that concerned the founders of lean project delivery. They too wondered if fewer materials could create a product or whether their team members were spending time doing the right things.

How software helps establish stronger work habits

To eliminate waste in your home construction process, you need to have greater insight in how your project and its supply chain are running; you have to establish targets to measure your team’s success; and you need the right data to set a strategic vision that better predicts future project outcomes.

Increasingly home builders and renovators are turning to modern construction management software to generate this data, and the increasingly competitive builders are using cost-effective cloud software to serve as their lean production platform. With the right software, builders gain the necessary production control from which smart lean construction decisions can be based.

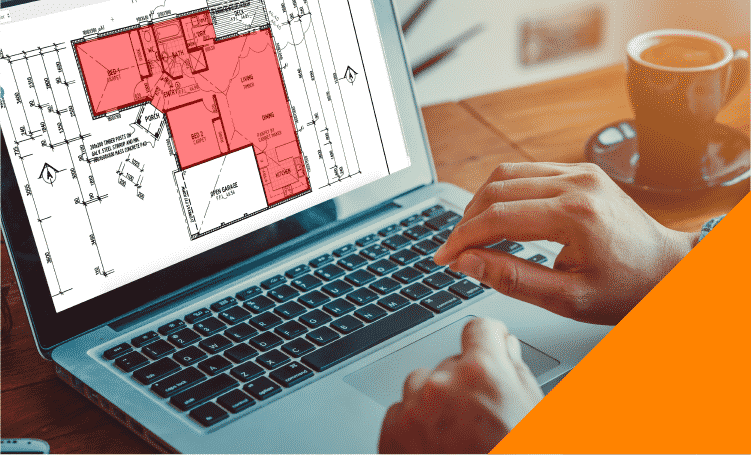

Planning a more profitable construction project

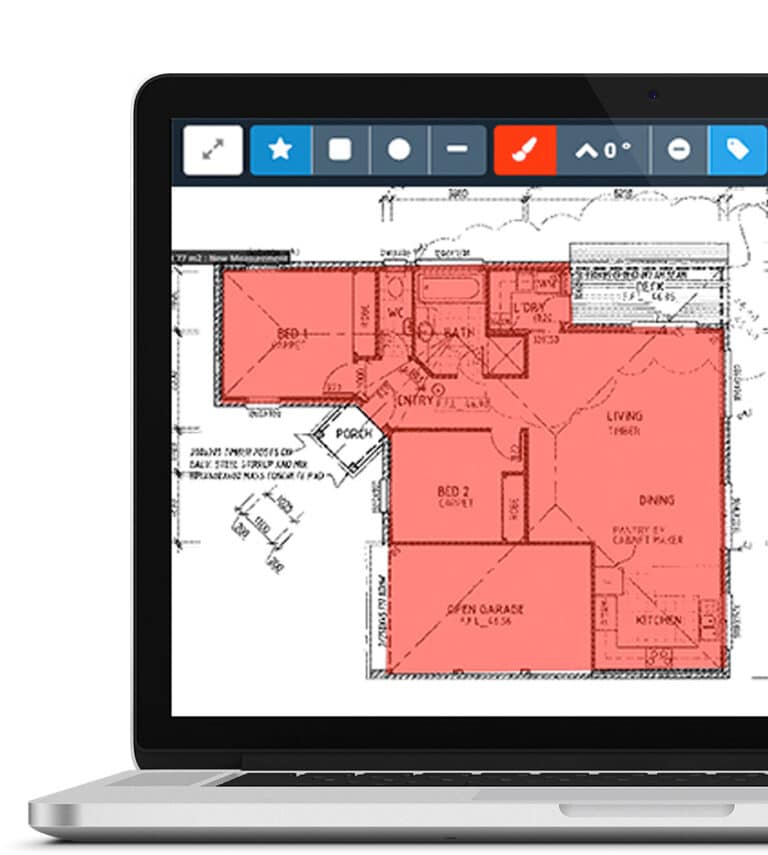

Profitability is all in the upfront planning, and today’s leading cloud-based home construction management tools offers accurate project estimating and quoting to prepare builders to run a successful project from its early stages to final invoicing. When using software, you generate a detailed estimate faster than traditional construction project tools. These modern estimates document all the critical tasks and the associated labor and material costs.

The estimate and quote not only fully informs your homeowner of what to expect but also forces conversation among you and your tradies about the quantity and quality of materials and the necessary time for installation. Get everyone on the same page before you hammer the first nail. You will find it is critical for cost control, scheduling and continuous improvement.

It also helps you figure out your core team of reliable subcontractors. Remember, subcontractors quoting the lowest cost or quickest turnaround may not be worth the upfront savings they promise you serving as the general contractor. You risk wasted materials and unplanned rework to correct poor workmanship.

In the lean construction process, rework, or what some refer to as defects, are a form of waste to avoid in the construction process because they generate expensive, disruptive variations.

Coordinating schedules avoids wasteful downtime

Today’s modern software makes estimating and quoting a fast and efficient process so that you close the sale more quickly. Once the homeowner commits to the project and you’ve designated your team to do the site prep, framing and other tasks, you then can jumpstart the actual build of your home project.

Here again, the basic concepts of lean management help you gain project control. When deciding how work should flow from one phase of the build to the next, you have to coordinate and schedule ahead of time the arrival of materials, equipment and the skilled subcontractors who work your job site. You can’t afford to have team members waiting for materials. Lean construction practices demand that there should be no waiting and no downtime.

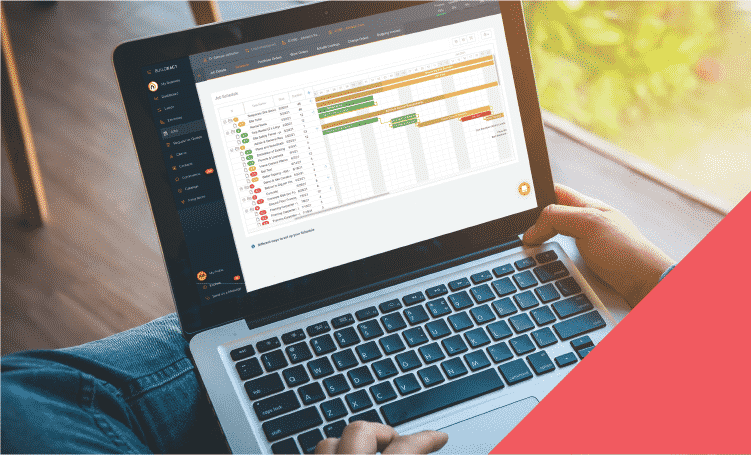

Modern software helps you avoid downtime through detailed scheduling tools that allow you to use features like color-coded Gantt charts to see how work is progressing and what jobs depend on another task’s completion.

The right software allows you to adjust schedules and material deliveries in real time with simple, point-and-click computer mouse commands that use the same job categories that were used in the original estimate.

Everything stays neat and organized to minimize waste. By tracking schedules for each job, you will learn as each job is completed the ideal time it should take for specific tasks.

Using budgets to benchmark your construction activity

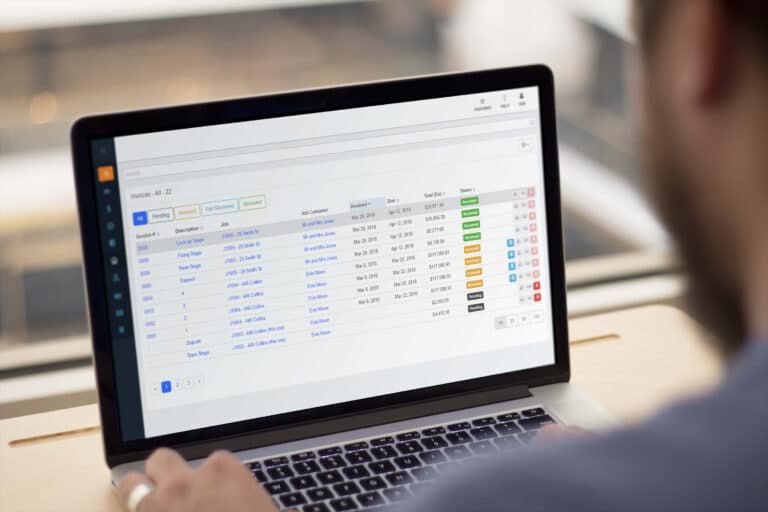

The best software also offers budget and invoicing line items for the many tasks required to complete a home build. Tracking expenses by tasks and categories gives you the ability to see what parts of your project bring the greatest value. In terms of lean principles, this is what is known as identifying your top value stream.

Whether it be framing, roofing, or plumbing, you want to know where your team is the most efficient and where the greatest costs lie. You want to continue doing what you do well so that you can focus on improving the wasteful and expensive areas in future projects. It might mean hiring a new set of subcontractors who work more efficiently or perhaps it means finding a more affordable supplier for the materials involved with that costly work.

How to adopt lean construction in your business

Many home builders like you are using Buildxact as their lean management platform. Buildxact offers time-saving digital takeoffs, estimating and scheduling for a low monthly subscription. Want to learn more? Book a demo or free 14-day trial today!